In the ever-evolving landscape of construction and architecture, the demand for durable, versatile materials continues to grow. Among these, corrugated sheet steel panels have gained significant prominence. These panels, characterized by their wavy design, are celebrated for their lightweight yet robust properties, making them an ideal choice for various applications, including roofing, siding, and even flooring.

When it comes to roofing, one of the most crucial components is the roofing sheet. These sheets provide shelter and protection to buildings, ensuring that they are safe from the elements. Selecting the right roof sheet size not only impacts the aesthetic appeal of a structure but also influences its durability and overall performance. In this article, we will explore standard roof sheet sizes, their importance, and how to find reliable suppliers.

Before diving into supplier options, it’s important to understand why metal planter boxes are favored by many. Firstly, they are exceptionally sturdy, able to withstand harsh weather conditions without warping or cracking, unlike their wooden counterparts. Materials typically used include galvanized steel, corten steel, and aluminum, each offering unique aesthetic qualities and levels of durability.

The first thing to look for in a tin can supplier is the quality of their products. High-quality tin cans should be robust, rust-resistant, and capable of withstanding varying temperatures while ensuring a hermetic seal. Suppliers should adhere to industry standards and regulations, including FDA guidelines, to ensure food safety. Before committing, it is advisable to request samples and conduct tests to evaluate the cans' strength and sealing capabilities.

Metal roofing has become a popular choice for both residential and commercial buildings due to its durability, energy efficiency, and aesthetic appeal. As the demand for metal roofs continues to rise, so does the need for high-quality components that ensure their longevity and effectiveness. One of these critical components is roofing boots, which play a significant role in providing waterproofing and protection for roof penetrations, such as vents and pipes. In this article, we will explore the importance of metal roofing boots and highlight some prominent manufacturers in the industry.

The raw materials used in the production of roof sheet fixings are critical for their performance and durability. Commonly used materials include stainless steel, carbon steel, and galvanized steel, all of which provide resistance to corrosion and wear. Once the materials are selected, they undergo a detailed process that usually begins with cutting and shaping. Factories utilize a variety of machines, such as lathes, presses, and CNC (Computer Numerical Control) machines, to create precisely engineered fixings that meet the stringent demands of the roofing industry.

When exploring suppliers for corrugated sheet metal roofing, it’s important to note the various options available. Depending on the aesthetic goals and functional requirements, consumers can choose from different materials, gauges, and finishes. Galvanized and galvalume steel are common choices for those seeking strength and resistance to rust, while aluminum offers a lightweight alternative with excellent corrosion resistance.

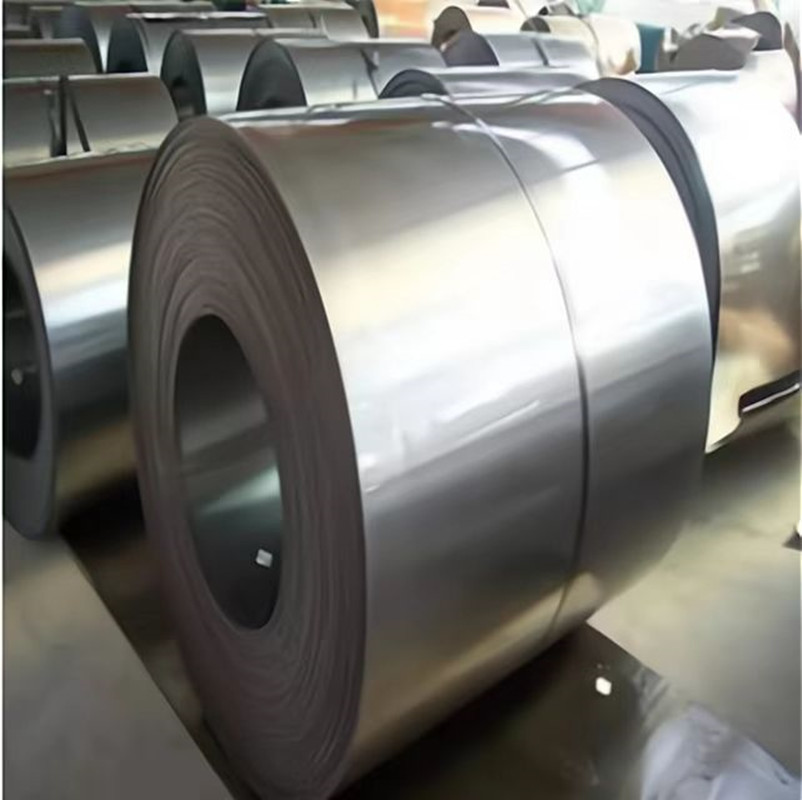

In summary, coil metal roofing presents an array of benefits including durability, eco-friendliness, design versatility, low maintenance, and cost-effectiveness. As homeowners and builders continue to seek sustainable and long-lasting solutions, coil metal stands out as a premier choice for roofing materials. Whether you are planning a new construction or a renovation, consider the impressive advantages of coil metal to enhance your property.

The choice of a flat roof cap sheet manufacturer is pivotal for achieving a reliable and long-lasting roofing system. By considering factors such as material quality, certifications, product range, technical support, and sustainability practices, builders and homeowners can make informed decisions that ensure the integrity of their flat roofs. As the demand for flat roofs continues to rise, so too does the importance of relying on trusted manufacturers to provide high-quality cap sheets that meet the evolving needs of a modern architectural landscape. Remember, investing in quality materials today can prevent larger expenses and repairs in the future, making it a wise choice for any building project.

In conclusion, finding the right galvanized iron sheet metal supplier is vital for any construction or manufacturing project. Prioritize quality, reputation, pricing, and customer service when making your selection. With the right supplier, you can ensure your projects are built on a foundation of high-quality materials that enhance durability and performance. Whether you're constructing a new building or fabricating metal products, invest time in choosing a supplier that aligns with your business values and project goals. This choice not only influences the success of your current venture but also sets the stage for future collaborations and projects.

The establishment of galvanized iron square pipe factories is influenced by several factors. Firstly, the skyrocketing demand for lightweight, long-lasting materials in construction has prompted manufacturers to invest in modern production techniques. These factories are equipped with advanced machinery that allows for the mass production of high-quality pipes that meet international standards. Automation and technology have enabled factories to increase efficiency, reduce waste, and lower production costs, making galvanized iron square pipes more accessible to consumers.